Dynamic polymer materials

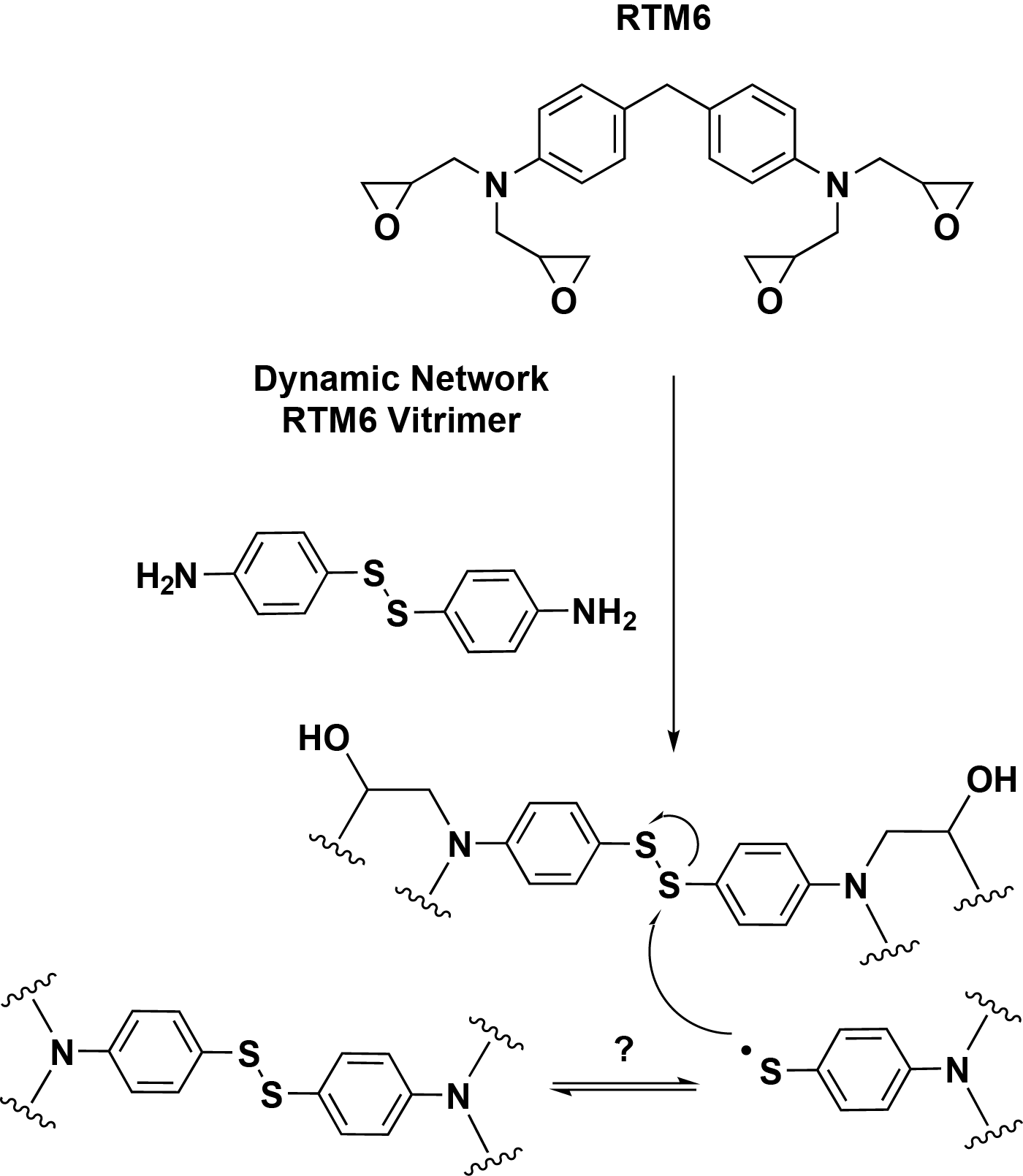

Dynamic covalent exchanges introduced into polymer networks is a very attracting strategy as it enables the combination of the easy processing of thermoplastics, and the high durability and resistance of thermosets. Associative dynamic chemistry present in vitrimers is particularly interesting as this class of materials can be reshaped, reprocessed, repaired, or recycled at high temperature while remaining highly infusible and insoluble.

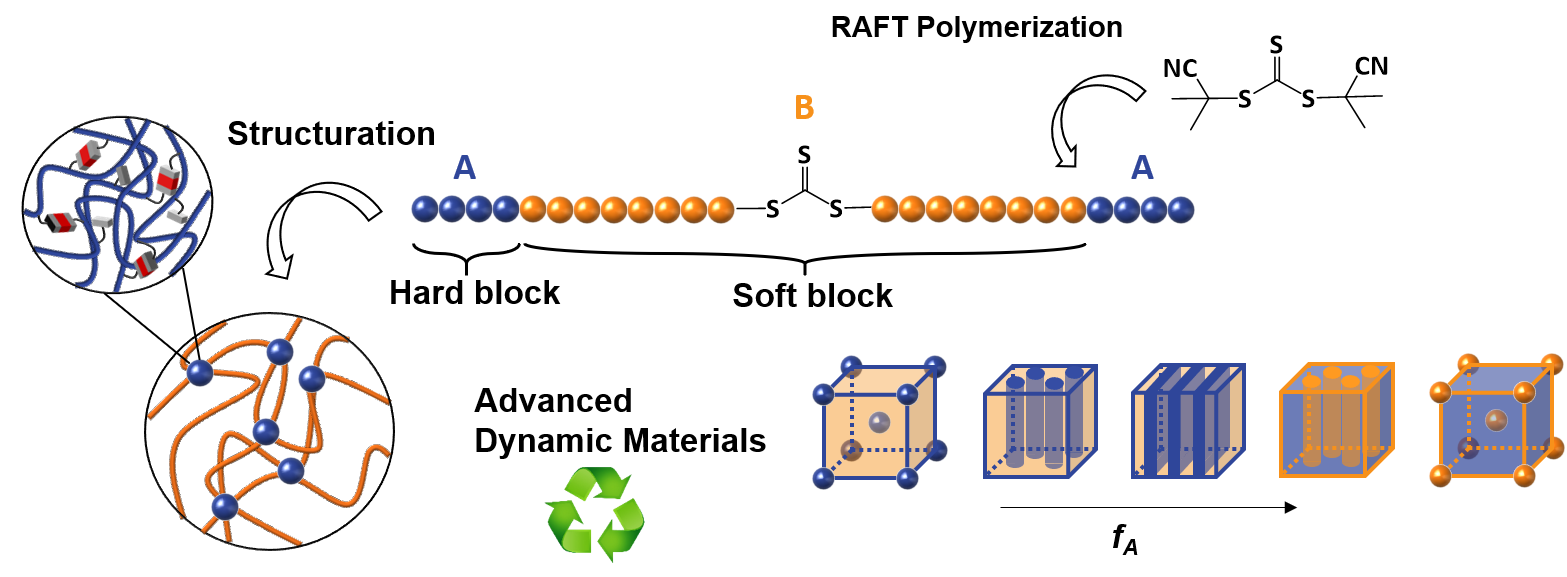

One of our research activities consists in combining our expertise in RAFT polymerisation with the dynamic chemistries of vitrimers to prepare nanostructured copolymers with reinforced properties. We take advantage of our recently developed symmetrical trithiocarbonate derived from 2-cyanopropan-2-yl group to prepare ABA triblock copolymers with different hard/soft ratio resulting in materials with various morphologies such as cubic, cylindrical, gyroid, etc. The dynamic functionalities introduced through simple copolymerisation enable the preparation of dynamically crosslinked nanostructured elastomers with improved thermomechanical resistance while maintaining high recyclability.

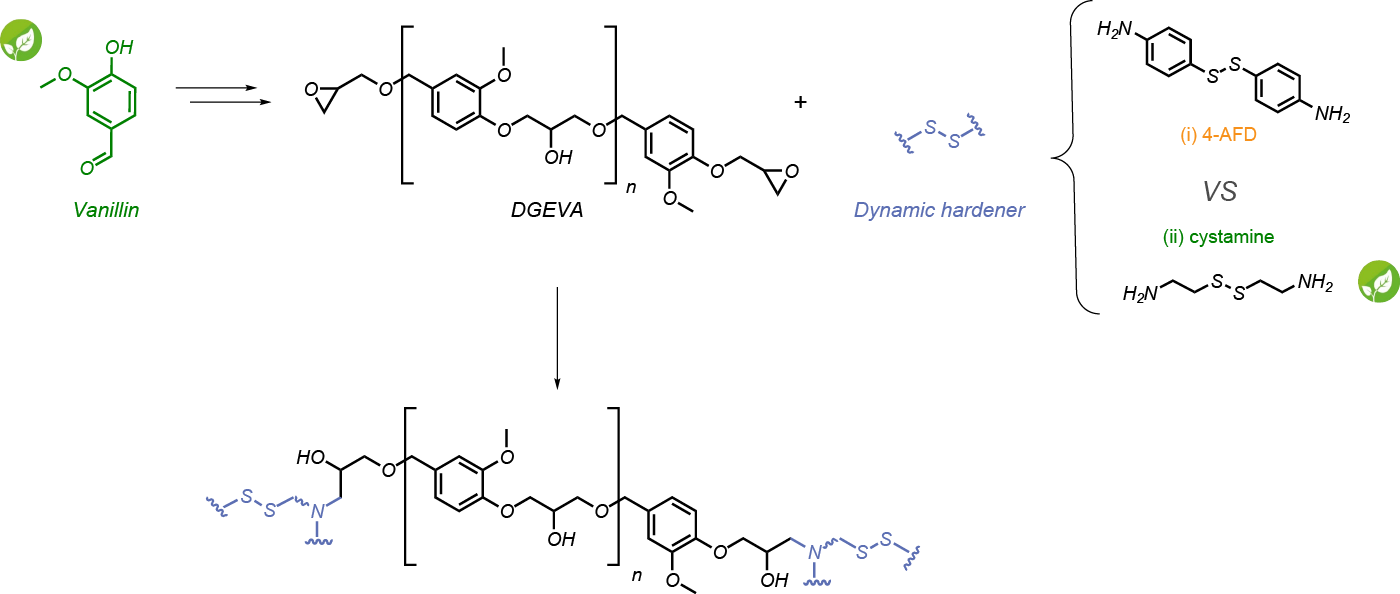

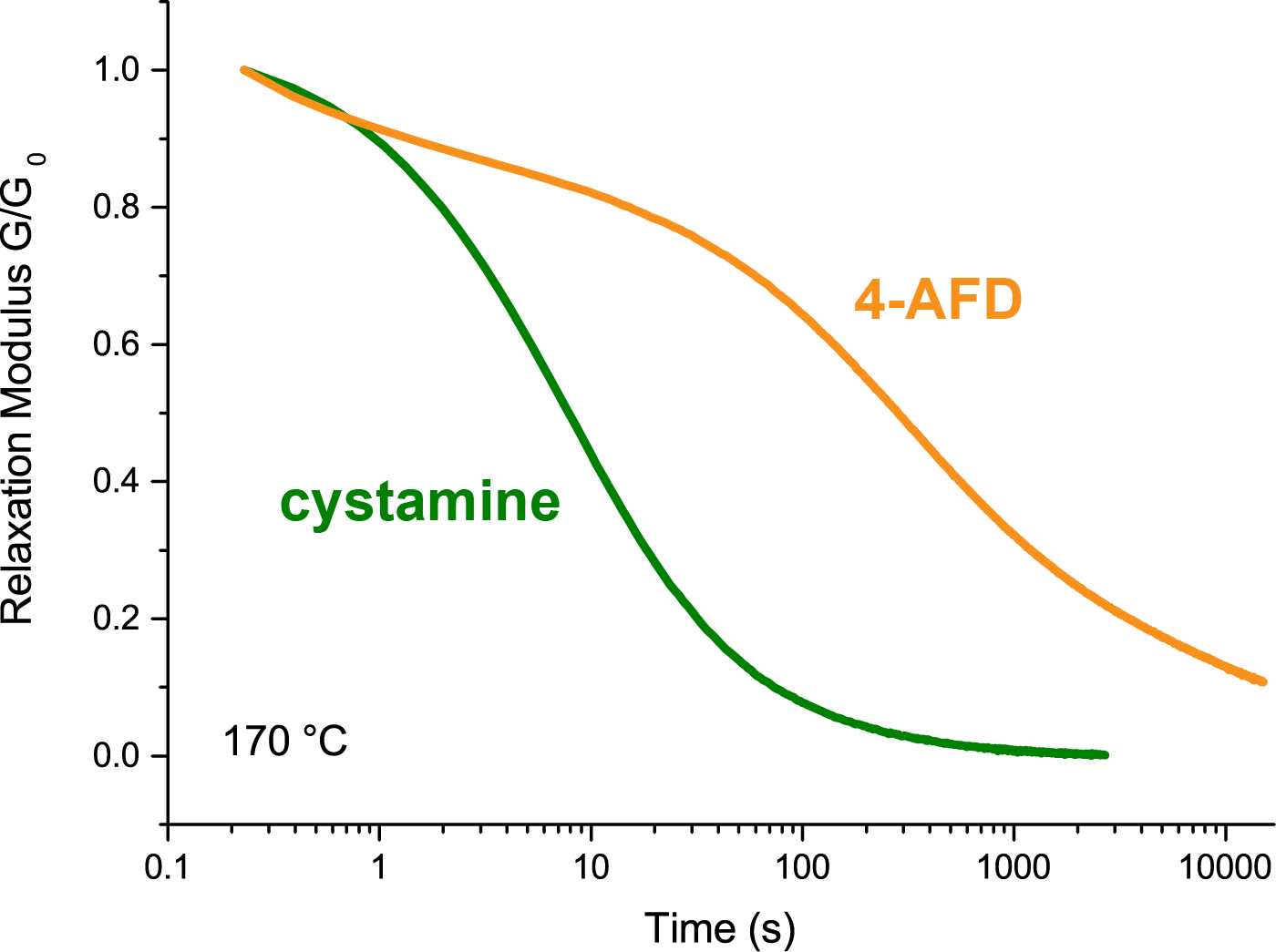

In a second approach, we developed a fully bio-based formulation using vanillin and cystamine, a reactive aliphatic diamine disulfide derived from an amino acid which appears as a suitable hardener in the context of dynamic materials. Our findings revealed that, although cystamine exhibits lower radical concentration at high temperature than the widely used petro-based dynamic hardener (4AFD, 4-aminophenyl disulfide), cystamine-based vitrimers are much more dynamic.

In addition, our study demonstrates that the addition of cystamine in 4AFD-based formulations enables a fine tuning of the exchange dynamics.

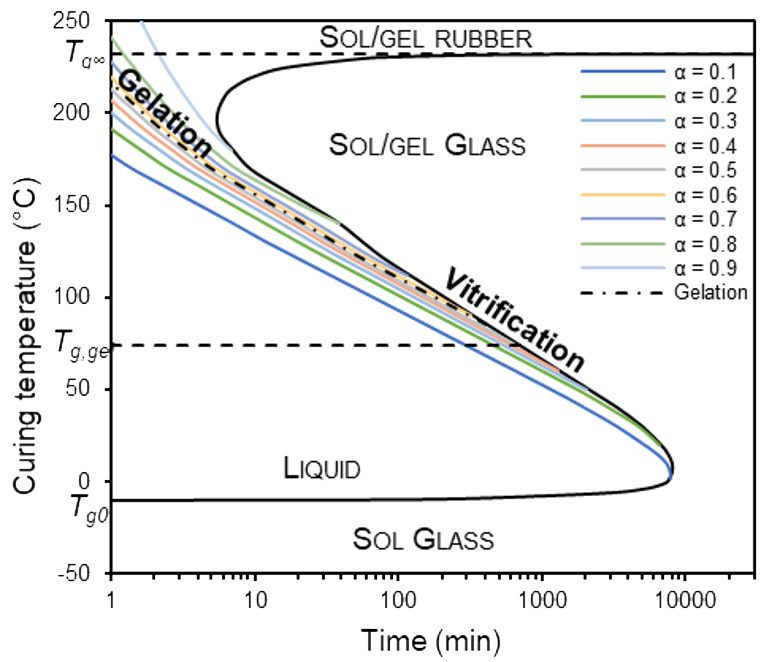

With diverse local partners, we are actively involved in the implementation of vitrimer chemistries into high performance composites applications. For instance, we were the first to report a time-temperature-transformation (TTT) diagram for a vitrimer system. This diagram is mandatory to perfectly control the processing and curing parameters during resin transfer moulding (RTM) process.