Development & characterisation of formulations & complex assemblies

We design and characterise complex assemblies, which result from the integration of organised systems in complex matrices, leading to applications in various industrial domains (food, cosmetics, materials for aeronautics, environment, health), by the development of formulations, gels loaded with nanoparticles or vesicles, organogels, porous materials, patches.

The designed formulations are then characterised to link their composition to the properties required in the applications.

Thus, we combine physicochemical techniques (mechanical properties, colloidal stability, etc.) and analytical techniques (NMR, HRMS, chromatography, IR) to characterise the assemblies and the interactions involved in these systems.

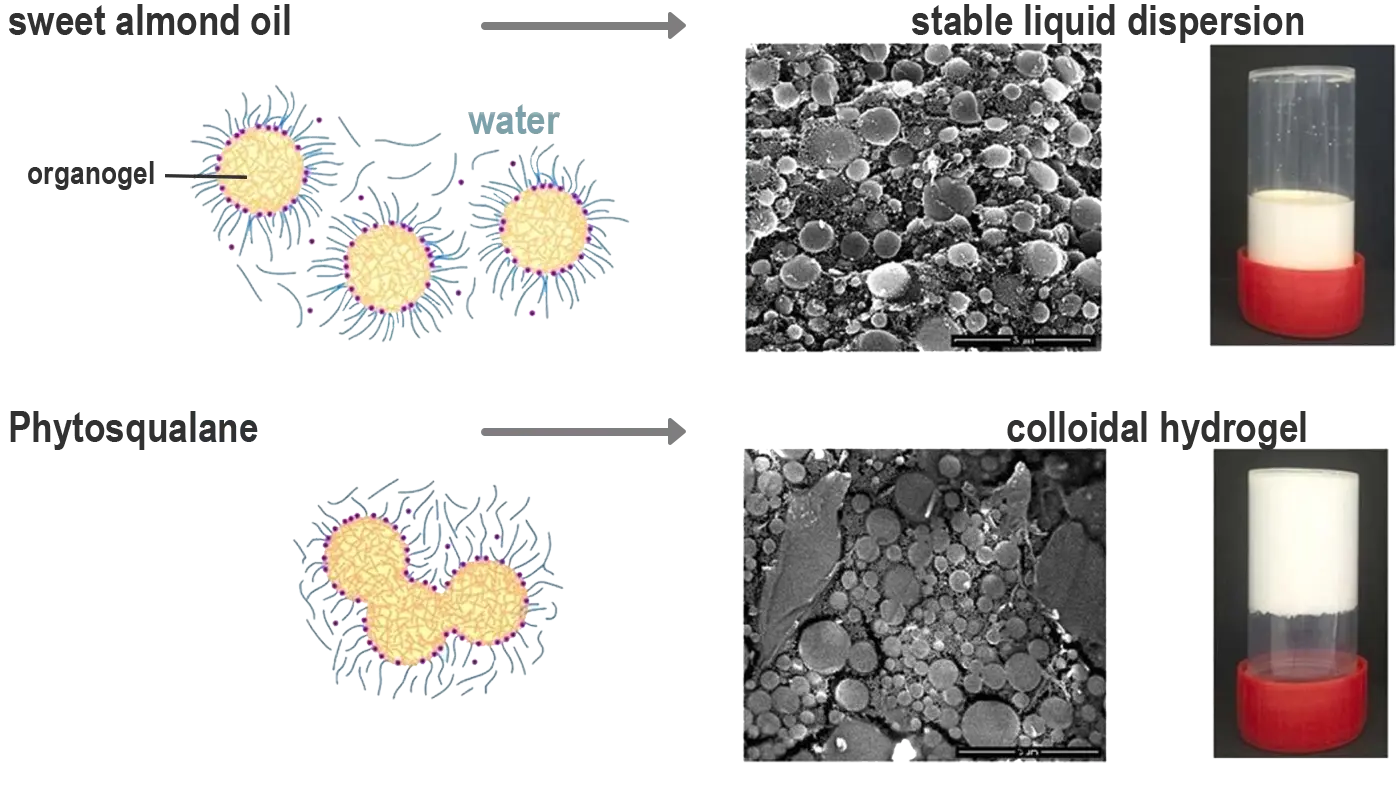

For example, in the cosmetics field, we are working on developing new textures, both from a performance and sensory point of view.

Thus, we have developed aqueous dispersions of organogel particles of various textures depending on the vegetable oil used: a stable dispersion of organogel particles or a colloidal hydrogel.

We could thus understand the impact of the ingredients on the formed textures, and propose different formation mechanisms. The obtained results pave the way to new textures in the cosmetic or pharmaceutical fields.

Aqueous dispersions of organogel particles with various textures

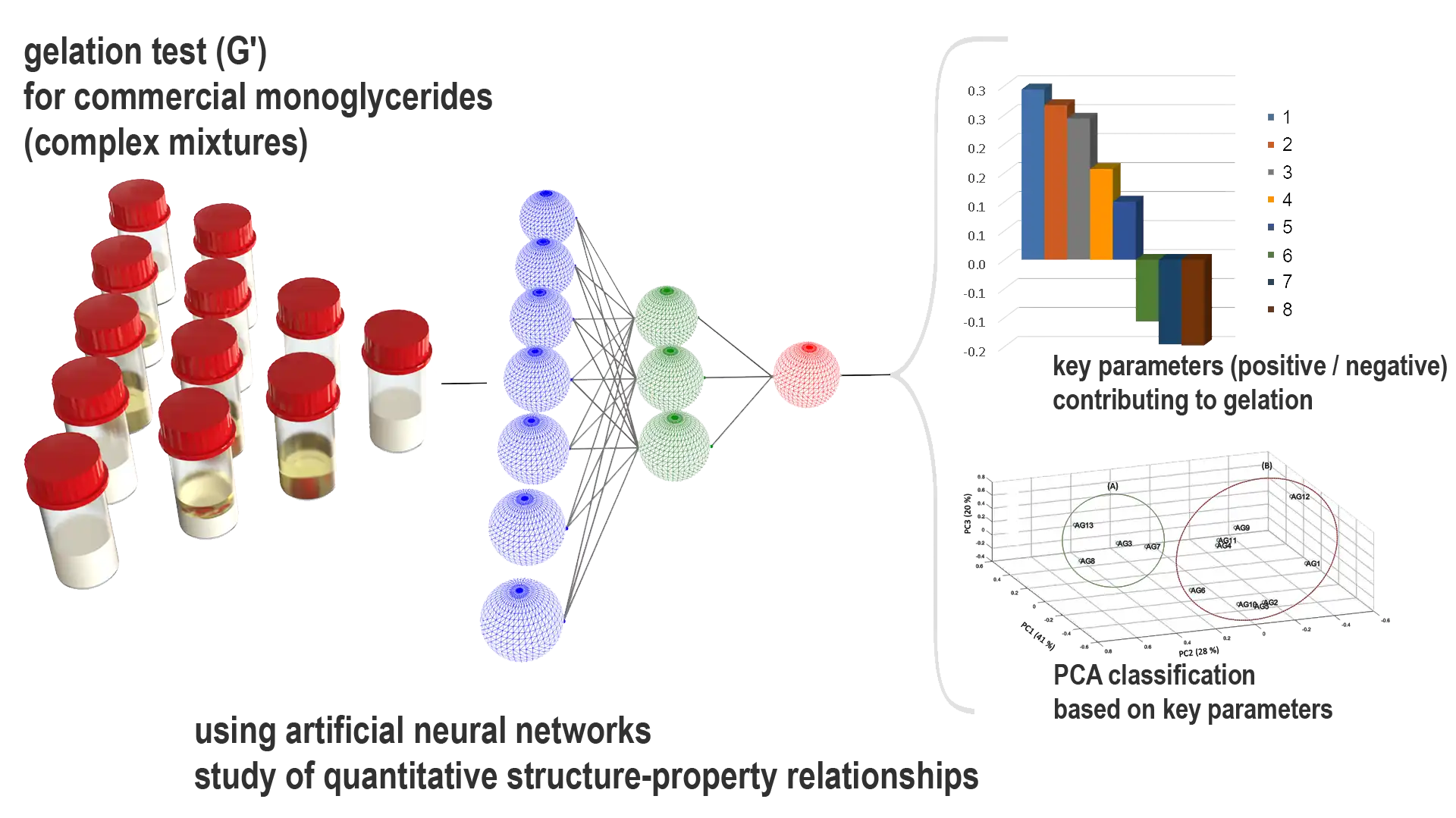

Chemometric approach linking the compositions of formulations to the properties of gelation

We are also interested in complex mixtures of natural origin. Thus we integrate the molecular and structural diversity found within natural matrices to formulate different complex systems. The integration of these bricks allows us to save purification steps, to offer original formulations in which the synergies are optimized and controlled for targeted applications.

In the case of complex mixtures of natural origin, the identification of each component is not always possible, so the team is developing original methods to classify the constituents into specific families. Modifications of the properties of these mixtures are also carried out, in order to address and identify the molecular diversity involved.

Thus we have, for example, developed a chemometric approach to identify the key parameters involved in the gelling processes of organogelators. This original approach makes it possible to classify and evaluate the impact of ingredients on the properties of complex mixtures and thus better integrate them into new formulations.